Monoclonal antibodies (mAbs) are frequently used to obtain excellent specificity against a wide range of extracellular targets. mAbs offer many applications in detecting and treating disorders such as cancer, autoimmune diseases, sexually transmitted infections (STIs), and many others. Because of considerable breakthroughs in design, the adoption of mAbs has grown tremendously in recent years.

Several factors have played a significant role in enhancing therapeutic mAb profiles. These factors include reduced immunogenicity in humans, increased bioavailability, improved affinity, antigen-binding selectivity, and other developments in protein engineering.

This post will go through the process of producing monoclonal antibodies and how various approaches are used. Continue reading to discover more about mAbs.

What is Monoclonal Antibody Production?

Monoclonal antibodies are created by cloning a single white blood cell to produce a cell line. All subsequent antibodies produced in this manner may be traced back to a single parent cell.

Monoclonal antibodies have monovalent affinity, binding to the same epitope (the part of an antigen that the antibody recognizes). On the other hand, polyclonal antibodies bind to several epitopes and are often produced by numerous antibody-secreting plasma cell lineages. Bispecific monoclonal antibodies may also be created by expanding the therapeutic targets of a monoclonal antibody to include two epitopes.

It is possible to manufacture monoclonal antibodies that selectively attach to any appropriate substance, which detects or purifies it. These techniques have become crucial in biochemistry, molecular biology, and medicine. Several disorders are being diagnosed and treated using monoclonal antibodies in clinical settings.

Milstein and Köhler developed monoclonal antibodies in 1975, ushering in a new disease diagnosis and therapy era. Their broad availability has been made possible by the advent of cell culture-based production techniques. Monoclonal antibodies can be produced in several techniques, including:

Laboratory production

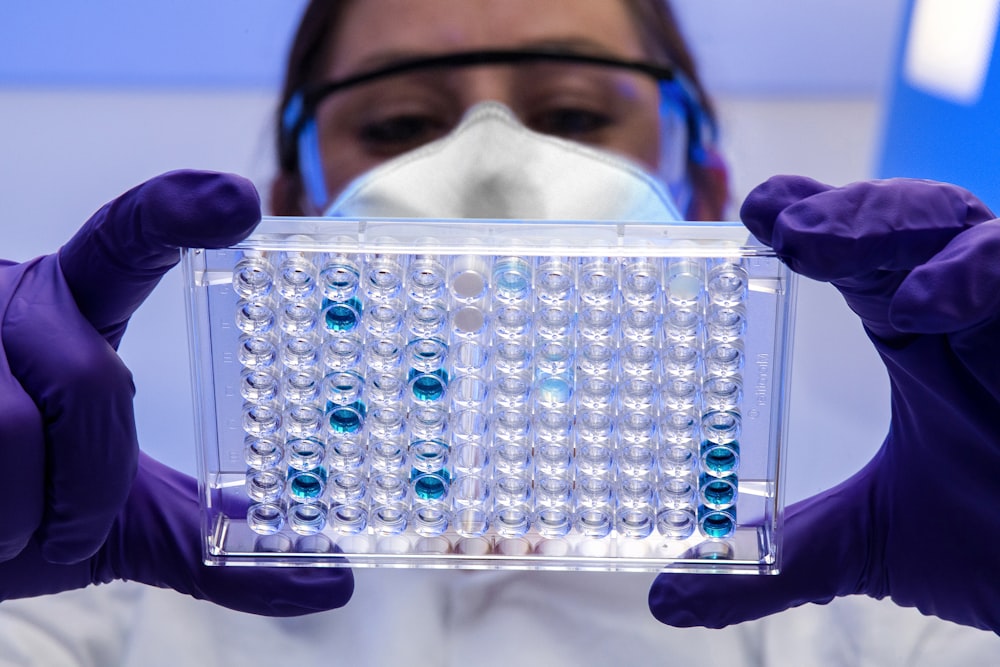

The industrial manufacture of monoclonal antibodies begins in the laboratory by introducing an antigen (a chemical capable of eliciting an immune response) into a lab mouse. The mouse’s antigen, in turn, creates B lymphocytes (antibody-producing cells) to protect itself. These cells live for a short spell before fusing with immortal tumor cells (typically myeloma cells), resulting in hybridomas (immortal cells that can produce antibodies).

Several B lymphocyte clones against the antigen have been isolated from mice, resulting in hybridomas capable of producing a variety of antibodies against the antigen. These antibodies are a combination of polyclonal antibodies.

The hybridomas derived from a single B lymphocyte are then chosen, generating an immortal cell that generates just one type of antibody known as the monoclonal antibody.

The human body can reject the antibodies generated by hybridomas in mice (they are recognized as foreign and trigger the immune response). Humanized antibodies, in which only the antibody component that identifies the antigen comes from mice, have been created using methods like those used to create antibodies generated by the human body.

Industrial production

Humanized antibodies are created using genetically engineered cells. Mammalian cells are the best, with Chinese hamster ovary cells being the most utilized. Cells must meet certain pH, temperature, oxygen, nutrients, culture medium, and more to reproduce and generate antibodies. Each company determines the most suitable conditions for the antibody it wishes to generate.

Bioreactors are containers that hold cells and culture medium. Those in which the cells are suspended in a liquid culture medium are the most efficient.

There are several types of bioreactors, and they vary based on factors such as whether they are disposable, how they aerate the culture, regulation of optimal conditions, and collection of manufactured antibodies.

To avoid contamination, producers prefer using disposable or single-use bioreactors. These bioreactors are more flexible, allowing modifications in the therapeutic product to be created at unprecedented speeds. They also eliminate the chance of cross-contamination during the production process.

Due to the industrial efficiency of this technology, we can also use fewer resources during production. For example, these bioreactors cut water use by 80% and cleaning agents by 90%, which makes our facilities less harmful to the environment.

The antibodies collected from the bioreactor are purified and concentrated for use in manufacturing pharmaceutical products.

Final Thoughts

How are monoclonal antibodies created? We hope you’ve found your answer. There is no one-size-fits-all manufacturing solution. What is appropriate for one procedure or manufacturing site may not be appropriate for another.

Monoclonal antibody sales account for half of all biopharmaceutical sales, totaling $75 billion. For several years, novel antibody creation approaches and production procedures have improved, facilitating market introduction and scale-up production. Consequently, the demand for high-quality biologics will continue to rise in the coming years.

The processes are generally the same as those used to schedule other bioproducts or biosimilars made by growing microorganisms or cells. This necessitates the creation of an efficient culturing process that incorporates all the control and related operations that will facilitate technical evaluations.

We face a significant challenge as regulatory authorities continue mounting pressure to improve quality and reduce monoclonal antibody production costs. Changes in plant design will play a substantial role in achieving highly adaptable multi-purpose facilities for small production quantities.